heating circuit distributors for Hot Capillary Tube Mat the capillary tube radiant save energy

Installation:

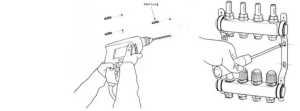

First step:Before installation the flow manifold bar needs to be twisted around so the flow gauges are on top with the connections below(as per pictures), to do this loosen the securing screws, twist the bar to correct orientation and re-tighten the screw. The manifolds are packed in this way to protect the flow gauges whilst in transit.

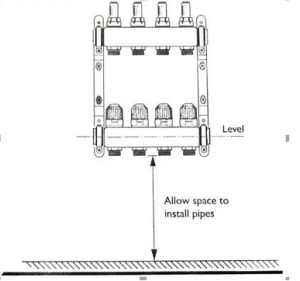

Second step:Make sure that the manifold is level and that it is high enough so that the pipes can be installed easily.

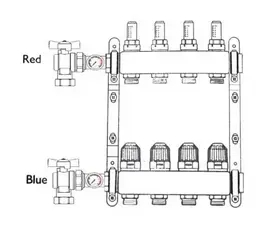

Third stept:Fit the blue handled 1″ union ball valve to the return manifold and the red handle 1″ union ball valve to the flow manifold.

Use the screws and plugs provided to mount the pre-assembled flow and return manifolds assembly to the ball (please ensure that the screws and plugs provided are appropriate for your wall construction,if not alternative suitable fixings should be used)

Please note :The blanking plugs should be fitted on the drain/filling valve.The manifold is now ready to have the flow and return pipes and the UFHC temperature control unit attached.

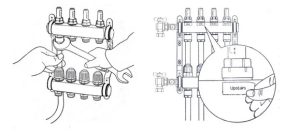

Ensure the tube is cut squarely and is not damaged.

After the installation is complete the identity stickers can be used (if desired), to identify which zone each loop of pipe serves.

heating circuit distributors for Hot Capillary Tube Mat the capillary tube radiant save energy

Nylon or Stainless steel distributor 9 underfloor heating circuits

Heating distributor

Product feature:

1. 304 stainless steel(food grade, nickle>8%) 100% material guranteed

2. Excellent surface treatment, 3/4″ unicon connector

3. Swiss made intelligent flow meter for monitor the flow rate

4. Dislocation mounting brackets

5. Each set strictly QC tested, won’t cause any leakage in usage

6. Each set in an inner box packing for your easy carrying

7. Max working pressure: 1.0Mpa

points, automatic air vents.prse-assembled distribution manifold for immediate mounting for both radiator and underfloor systems

1,Available in 1″ and 1-1/4″ sizes, from 2 ways to 12 ways with flow control valves to suit a wide range of system requirements

2,Can be surface mounted, concealed in a choice of purpose designed plastic or metal cabinets or within a partition wall for a

flexible solution to location

3,Manifold flow and return outlets are offset for space saving and ease of installation

4,Ball valves, fittings and pipe connectors for a wide range of pipe types and sizes

Technical date:

Material: main pipe 304 stainless steel

Medium: water(Max. percentage of glycol is 30%)

Operating pressure: PN16

Medium temperature:0-100 degree C

Connection: 1″ , 1-1/4″

Outlet: 3/4″*18

Adapter: 16*2.0mm , 20*2.0mm

Distance between outlets:50mm

Installation:

First step:Before installation the flow manifold bar needs to be twisted around so the flow gauges are on top with the

connections below(as per pictures), to do this loosen the securing screws, twist the bar to correct orientation and re-tighten the

screw. The manifolds are packed in this way to protect the flow gauges whilst in transit.

Use the screws and plugs provided to mount the pre-assembled flow and return manifolds assembly to the ball (please ensure that

the screws and plugs provided are appropriate for your wall construction,if not alternative suitable fixings should be used)

Pressure testing

100% QC pressure testing before packing.

Inner box packing

Master carton packing

Each set in an inner box packing, 5 sets / master carton box packing.

Pallet or wooden box packing

Strong packing to well protect the goods in transportation.

评论

发表评论